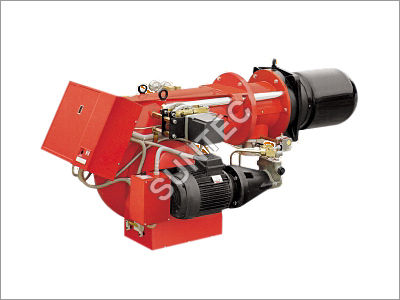

Two Stage Dual Fuel Burner

Product Details:

X

Product Description

We have emerged in offering our valuable customers with Two Stage Dual Fuel Burner. The fuel burners are widely demanded in the market as these products are very durable and deliver high performance especially when used with pressurized boilers. Expert professionals manufacture these products at our vendors base by using high quality components and materials. These burners can either be operated with gas or light oil. We are able to offer the Two Stage Dual Fuel Burner in various specifications to meet the needs of our customers.Other details Of Two Stage Dual Fuel Burner :

The GI/EMME 300-900 series of burners covers a firing range from 107 to 922 kW. They have been designed for middle and high output users and they are in particular suitable for matching with pressurized boilers. Their use allow to have an high safety in operation, guaranteed from the double fuel supply.

Technical Data Of Two Stage Dual Fuel Burner :

| Model | GI/EMME 300 | GI/EMME 400 | GI/EMME 600 | GI/EMME 900 | ||

| Burner operation mode | Two stage | |||||

| Modulation ratio at max. output | 2:1 | |||||

| Servomotor | run time | type | LKS 210 | |||

| s | 5 | |||||

Heat output | kW | 107/175 - 332 | 116/232 - 465 | 174/348 - 665 | 250/525 - 922 | |

| Mcal/h | 92/150 - 286 | 100/200 - 400 | 150/299 - 572 | 215/452 - 793 | ||

| Working temperature | oC min./max. | 0/40 | ||||

| Fuel / Air Data | ||||||

Oil | Net calorific value | kWh/kg | 11,8 | |||

| Viscosity | mm2/s ( cSt) | 4-6 (at 20oC) | ||||

| Delivery | kg/h | 9/15 - 28 | 10/20 - 39 | 15/29 - 56 | 21/44 - 78 | |

| Pump | type | AN 67 | AN 67 | AN 77 | AN 97 | |

| Delivery | kg/h | 75 at 12 bar | 75 at 12 bar | 100 at 12 bar | 120 at 12 bar | |

| Atomised pressure | bar | 12 | ||||

| Fuel temperature | max oC | 60 | ||||

| Fuel preheater | NO | |||||

G20 | Net calorific value | kWh/Nm3 | 10 | |||

| Density | kg/Nm3 | 0,71 | ||||

| Gas delivery | Nm3/h | 10,7/17,5 - 33,2 | 11,6/23,2 - 46,5 | 17,4/34,8 - 66,5 | 25/52,5 - 92,2 | |

G25 | Net calorific value | kWh/Nm3 | 8,6 | |||

| Density | kg/Nm3 | 0,78 | ||||

| Gas delivery | Nm3/h | 12,4/20,3 - 38,6 | 13,5/27 - 54 | 20,2/40,4 - 77,3 | 29/61 - 107,2 | |

LPG | Net calorific value | kWh/Nm3 | 25,8 | |||

| Density | kg/Nm3 | 2,02 | ||||

| Gas delivery | Nm3/h | 4,1/6,8 - 12,9 | 4,5/9 - 18 | 6,7/13,5 - 25,8 | 9,7/20,3 - 35,7 | |

| Fan | type | Centrifugal with forward curve blades | ||||

| Air temperature | max oC | 60 | ||||

| Electrical data | ||||||

| Electrical supply | Ph / Hz / V | 1/50/230 (+ 10%) | 3N/50/230-400 (+10%) | |||

| Auxiliary electrical supply | Ph / Hz / V | 1/50/230 (+10%) | ||||

| Control box | type | LFL 1.333 | ||||

| Total electrical power | kW | 0,5 | 0,62 | 1,1 | 2 | |

| Auxiliary electrical power | kW | 0,1 | 0,1 | 0,2 | 0,35 | |

| Heaters electrical power | kW | -- | ||||

| Protection level | IP | 44 | ||||

| Pump motor electrical power | kW | 0,15 | ||||

| Rated pump motor current | A | 1,4 | 2,85 | |||

| Pump motor start up current | A | 3,2 | 6,5 | |||

| Pump motor protection level | IP | 44 | ||||

| Fan motor electrical power | kW | 0,25 | 0,37 | 0,75 | 1,5 | |

| Rated fan motor current | A | 1,85 | 2,9 | 2,85/1,65 | 6,55/3,15 | |

| Fan motor start up current | A | 4,2 | 6,6 | 6,5/3,8 | 32,75/15,75 | |

| Fan motor protection level | IP | 44 | ||||

Ignition transformer | type | -- | ||||

| V1- V2 | 230 V - 1x8 kV | |||||

| I1 - I2 | 1,8 A - 30 mA | |||||

| Operation | Intermittent (at least one stop every 24h) | |||||

| Approval Emissions | ||||||

| Sound pressure | dB(A) | 69 | 74 | 82 | 84 | |

| Sound power | W | -- | ||||

Oil | CO emission | mg/kWh | < 30 | |||

| Grade of smoke indicator | N Bacharach | -- | ||||

| CxHy emission | mg/kWh | -- | ||||

| NOx emission | mg/kWh | < 200 | ||||

| G20 | CO emission | mg/kWh | < 60 | |||

| NOx emission | mg/kWh | < 120 | ||||

| Directive | 89/336 - 73/23 EEC | |||||

| Conforming to | EN 267 - EN 676 | |||||

| Certification | -- | |||||

Enter Buying Requirement Details